Our company is 100% focused on the sale of used CNC machines and equipment, only original machines, all our machines are delivered by a specialized technical team.

We offer services with CNC machines and equipment, both new and used.

If the customer chooses a new machine, we will recommend partners who represent the available brands and equipment. If the preference is for a used machine, we have options in our service portfolio.

We divide our operations into receiving, washing, inspection for maintenance, maintenance, sales to customers.

We are a company specialized in CNC machine programming.

We provide all accessories for your CNC machines.

We are a Process Engineering firm, where our acronym precisely reflects our specialized offerings as Development of Processes Specific between Controllers. Our overarching mission is to seamlessly integrate our advanced CNC programming services with businesses seeking to optimize manufacturing workflows through software solutions.

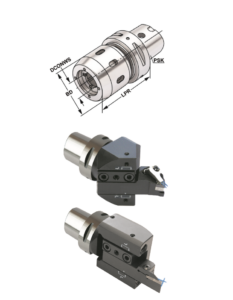

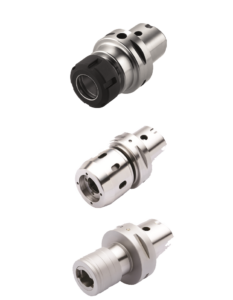

We specialize in providing accessories tailored for CNC machines, turning centers, machining centers, Swiss-type lathes, and wire erosion equipment. Our offerings extend beyond mere product provision; we offer customized solutions derived from our advancements. Additionally, we offer comprehensive post-purchase support services to companies seeking guidance and assistance in selecting and integrating accessories into their operations.

The MPS department serves as the nexus that establishes and fosters connections with all departments within the company. It bears primary responsibility for orchestrating the coordination of MRP-I & II processes—encompassing Material Requirement Planning (MRP-I) and Manufacturing Resources Planning (MRP-II).

Our accountability is delegated through the critical system overseeing the comprehensive supply of materials essential for executing processes tailored for CNC machines. Notifications of pertinent alerts are relayed to us by the MPS department.

Accessories, Clamp Holders ER11, ER16, ER20, ER25, Capto C3 - C10, BT30, BT40, BT50.

If your company requires outsourcing for production, our Make-to-Order department collaborates seamlessly with our Production Planning and Control Process department, ensuring readiness to fulfill production requirements. Our product monitoring services, conducted by our trusted partners, adhere to pre-established orders, complete with comprehensive quotations. Services are executed in accordance with technical drawings provided by the customer.

PSBC Group specializes in advanced 3D scanning technologies, along with part and product engineering, reverse engineering, and software and engineering services. Our solutions enable companies to efficiently and precisely measure complex parts and assemblies for quality control and reverse engineering purposes. With a team of skilled professionals trained in CNC machine programming, we boast specialized expertise, including 4 Swiss Type Machining programmers, 2 Machining Center programmers capable of up to 5 axes, and 4 Turning Center programmers equipped with 3 synchronized turrets, proficient in FANUC 03 channel commands. Serving clients across the EU, our clientele spans diverse sectors such as aerospace, automotive, maritime, power generation, industrial equipment, and the medical sector.

Our Total Quality Management (TQM) department embodies a management framework designed for a customer-centric organization, involving all employees in continuous improvement initiatives. By leveraging strategy, data, and effective communication, we seamlessly integrate the discipline of quality into the organization's culture and operations. It is essential to note that all our programs strictly adhere to ISO standard systems. Additionally, we emphasize the importance of customers providing us with 2D drawings, complete with their respective tolerances, as well as 3D drawings for the development of machining processes.

Our company is established within the framework of 4.0 Industry, where the delineation between its foundational principles, technological advancements, and their essential interconnections should yield positive environmental outcomes. In this revolutionary era, production intricately intertwines with information and communication systems, rendering it more adaptable, competitive, and well-informed. Industry 4.0 offers a spectrum of principles, guidelines, and technologies for the establishment and enhancement of both new and existing factories. This empowers consumers to select diverse production models with scalable robotics, information technology, and communication systems.

Industry-GO three Exclusive VPS Servers, in 05 different locations within Europe.

Switzerland, France, 02 in Portugal.

Projects with greater development challenges.

Delivery of development with total closure, engineering, casting, machining, assembly, delivery to the customer.